Introduction

Now, the Caldera software streamlines the entire printing process, from the preparation stage to the final product phase, which enhances the printing experience and enables users to focus on creativity.

This is an essay written about Caldera RIP Software, which is a software used to enhance the printing experience. It helps streamline the entire digital printing process: from the initial stages of preparation to the final portion of creating the product itself.

This essay intends to explore several of Caldera RIP Software's features, benefits, and how it operates in practice within different printing industries.

Understanding Caldera RIP Software

Caldera RIP Software is an advanced raster image processor designed to deal with the complex needs of today’s printing environments, and provide a bridge between on-screen digital designs and off-screen physical prints: Creating and producing graphics no longer take place in a mere hobbyist fashion, but become business-critical processes for a larger number of companies and organisations. Caldera offers the tools to be successful in such an endeavour, with powerful, reliable and cost-effective workflow solutions, in-house.

Key Features of Caldera RIP Software

With a full-featured feature set and operability that is easy but flexible and powerful, Caldera RIP Software ready for an extensive array of users and products.

Advanced Color Management

Another important feature is its sophisticated and highly accurate colour management system, which allows printers to reproduce the exact same colour across different media types and devices. ICC profiles, spot colour handling and calibration tools all facilitate this accurate colour reproduction on every substrate. These features are essential if you want your clients to keep doing business with you because branding is all about achieving that precise and consistent result.

Enhanced Print Quality

Caldera optimises output with the very latest algorithms to render and process images. The result is sharper, brighter and better-detailed output, with fewer artifacts than less advanced devices, whether that’s a single roll-to-roll design or a banner for a three-storey building. Caldera is dedicated to the highest quality print results, with every order to your best standard.

Versatility and Compatibility

And because of its flexibility, the same RIP software supports a large number of file formats, as well as various printers and cutters, from UV flatbeds to textile dye sublimation systems, from distortion printers to single-pass printers. Caldera adapts easily to different production environments, making transitioning easy and operating as cost-effectively as possible.

Benefits of Using Caldera RIP Software

Integrating Caldera RIP Software brings numerous advantages to the table in terms of operational efficiency and and unit costs, while optimising the overall workflow:

Enhanced Operational Efficiency

It takes over the everyday mundane, such as automatically reconfiguring print queues, minimising downtime and shortening job turnaround times. Caldera also integrates new printers quickly and intuitively – allowing operators with varying levels of expertise to easily manage complex workflows.

Cost Optimization

Optimise ink consumption with Caldera’s RIP Software and maximise material uses efficiency Accelerated production and automated imposition speed up the print queue, reduce delivery times and boost sales. Nesting and layout tools with higher concentration reduce substrate consumption to lower production costs and generate savings that benefit your profitability over time.

Streamlined Workflow Integration

Caldera fits in existing print workflows by integrating products with industry-standard software and hardware, ensuring interoperability with existing systems. Compatibility with well-supported supplier ecosystems ensures that installation is smooth, operations aren’t disrupted, and that everything runs efficiently.

How Caldera RIP Software Works

Caldera RIP Software transforms digital files into the correct printable formats for any given output device, from rasterisation to colour management and print queue optimisation, ensuring that every job prints as expected, every time.

Installation and User Experience

The installation and setup of Caldera RIP Software requires minimal effort. And thanks to automatically launching, step-by-step set-up wizards and extensive documentation, one can rapidly accomplish the job. Caldera strives to ensure the RIP supports a user’s workflow. The software features an interface and simplified workflows with shortcuts for key workflow steps, catering to less experienced users as much as those users knowing they only need a printer driver.

Caldera RIP Software vs. Competitors

Caldera's competitive edge lies in its performance reliability and customizable features:

Performance Reliability

Caldera’s features and support structure are the gold standard for reliability and proactively providing for all the needs of the industry, including those that are evolving mobile-first and social media-based marketing strategies. The promise of continuous updates and upgrades promises to stay evergreen with emerging industry standards and keep its operational smooth and client-engaging.

Customization and Scalability

For example, Caldera’s modular architecture is designed for flexible scaling, from single-device installations to large networked print farm environments, with the capacity for easy additions as your needs grow.

Applications of Caldera RIP Software

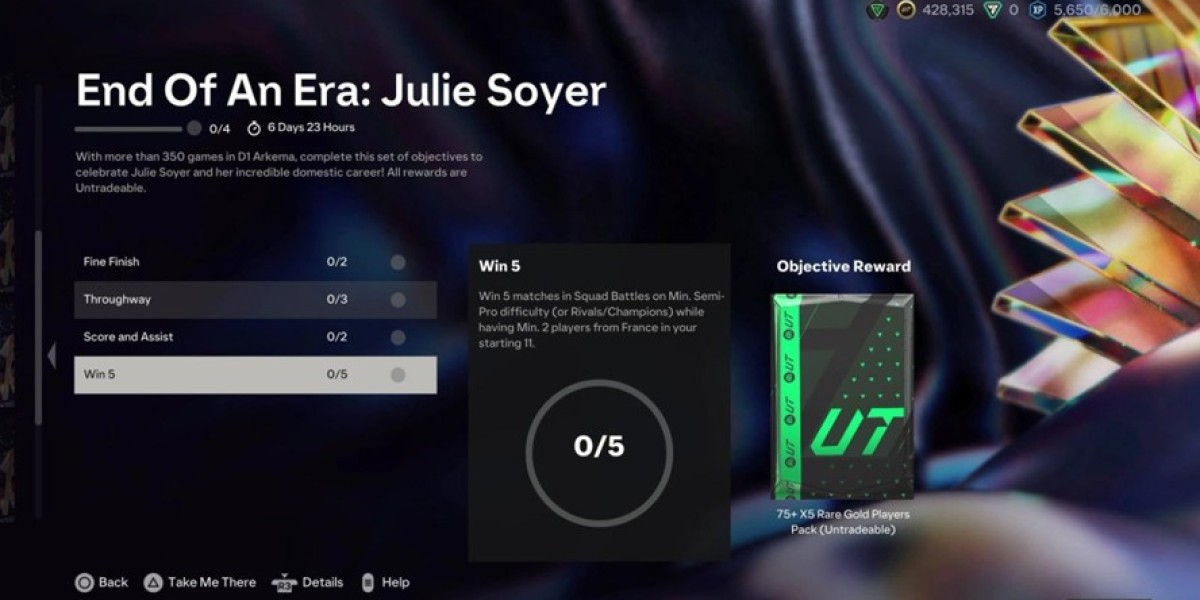

Figure 1. Smooth curves: seven calibrated curves for CalderaRIP Software. Courtesy of Caldera Graphics, Rixensart.Smooth curves: seven calibrated curves for CalderaRIP Software. Courtesy of Caldera Graphics, Rixensart. Figure 2. Process-colour generation for sheetfed printing: curves colour mixes with 100 per cent of CyanK (black) ink allow the printing of 61.2 per cent of HALFTONE-Process-full colour. Figure 3. Process-colour generation for sheetfed printing: curves colour mixes with 100 per cent of Magenta (black) ink allow the printing of 56.9 per cent of HALFTONE-Process-full colour. Figure 4. Process-colour generation for sheetfed printing: curves colour mixes with 100 per cent of Yellow ink allow the printing of 19.3 per cent of HALFTONE-Process-full colour. NOTE: Multiplying the percentages of ‘W – G’ (white-grey) and ‘B – B’ (black-black) ink allows one to determine the tonal range of the pantone numbers shown.Table 1. CMYK Values.From the calibrated curves, printers can construct colour curves and determine the tonal range of the pantone numbers used. For further sample Print Screen colour calibrations, please visit www.DDMscrolls.com. This technology can be applied across all printing fields, with each benefiting from its unique characteristics:

Large-Format Printing

For larger format print works, Caldera is the best in its class for printing signage, graphics and advertising with solid colour and higher resolution detail in every piece printed. It’s ideal for these types of large format printing applications which usually involve high cost and complicated tasks such as large size print, complex design, RIPing (rendering image processing), retouching image files, and precise positioning. Caldera is used in genres related to architecture such as architectural graphics and design, CAD data integration into large format printing, simulation printing, outdoor advertising, and event promotion.

Textile and Apparel Printing

In the textile industry, Caldera facilitates pinpoint colour matching and pattern repetition critical for providing accurate production details, all of which are important in the manufacture of clothing. Thanks to dedicated dye sublimation and direct-to-fabric print solutions, Caldera guarantees colours that withstand the test of time, remain consistent and fade-free, and adhere to today’s quality and market requirements.

Packaging and Specialty Printing

Beyond its headline museum application, Caldera has been applied in specialty printing – everything from packaging prototypes, labels and point-of-purchase signage to greetings cards, annual reports, book jackets and brochures designed by end users.The application’s versatility means that its toolset is always perfectly attuned to the products being considered, and is often customised to adapt the production parameters to tailor-made client needs.

Tips for Maximizing Caldera RIP Software

Maximize your utilization of Caldera RIP Software with these actionable strategies:

Regular Software Updates: Learn about the latest Caldera features and enhancements to leverage new programme functionalities and performance improvements.

By implementing colour calibration and profiling periodically, you can ensure that different substrates and printing conditions do not harm your brand name, or your relationship with your clients, by producing an inaccurate representation of colour.

Workflow Automation: Caldera’s automation ensures jobs are queued and printed in the correct order, layout parameters are optimised, last bits are toners reordered and things run smoothly, with minimal need for manual intervention.

Training and Support Resources: Benefit from Caldera’s robust training programs to sharpen your skills and access top-notch support resources for technical help.

Case Studies and Success Stories

Real-world examples underscore Caldera's transformative impact on print operations and client satisfaction:

A major print service provider found that production throughput increased by 30 per cent in the first year of using Caldera RIP Software, thanks to automation of their workflow and optimisation of the print scheduling processes.

Combining Caldera’s textile-based RIP features, focused on filament dyeing, the company was able to reduce its costs and maximise production. This helped scale the seasonal colour collections to market on tight deadlines.

Common Issues and Troubleshooting

Address common challenges with proactive troubleshooting strategies:

Colour Consistency: Remediate colour deviations by printer profile recalibration and ICC settings updating to deliver unified colours for a successful output between different print jobs on various medias.

Customise print queue management and job prioritisation so that printers are kept at maximum capacity during peak production periods, improving efficiency and client satisfaction.

Software Compatibility: Keep firmware updated and hardware V/C/C interpretations abreast, to avoid compatibility issues and system shocks plus downtime.

Future Developments and Updates

Caldera remains committed to innovation and customer-driven enhancements:

Future enhancements will add increased artificial intelligence (AI) automation and deeper cloud integration to boost workflow efficiencies and print quality standards.

This unceasing investment in research and development validates Caldera RIP Software as one of the field’s leading innovators in supporting new printing technologies and market needs.

Frequently Asked Questions (FAQs)

Addressing common inquiries facilitates informed decision-making and enhances user satisfaction:

Which printers are compatible with Caldera RIP Software?

Caldera has a broad range of printer models on its supported list, from large-format inkjet, UV flatbed, and textile-specific devices to more niche-market hardware. This compatibility enables dealers to pitch the solution across the entire scope of inkjet printing applications, from B2 pigments and CMYK roll-to-roll to dye-sublimation transfer with everything in between.

How does Caldera RIP Software ensure color accuracy?

‘Color management programming through Rich Black palettes controls colour reproduction to the boundaries of the media and/or printing conditions, resulting in faithful delivery to original design specs and what the client promised in their print presentation.’ Caldera utilises colour management algorithms and ICC (International Colour Consortium) profiling for fidelity of colour.

Is Caldera RIP Software suitable for novice users?

Yes, with Caldera the user has access to graphical interfaces that enable beginners to operate the system, while detailed documentation provides full support for expert users. This means that training personnel needs can be minimised.

Can Caldera RIP Software handle complex print jobs?

Indeed, its variety of nesting and tiling capabilities helps both with print layout and large-format graphic management in terms of substrate utilisation and print quality.

What support options are available for Caldera RIP Software users?

Caldera provides email and telephone replies to initial questions and problems, and also constantly upgrades its online knowledge bases (repositories of tips, how-to’s, and guidance) as well as user forums and dedicated technical support personnel.

Conclusion

Caldera RIP Software stands proudly as a world-class symbol of innovation and accuracy, bringing an unprecedented level of print quality and flexibility to your workflows. It is specifically designed to simplify your production processes, reduce your costs and increase your capacities for a wide range of printing applications. Take advantage of its features and turn to its user community to get the most from it. Welcome to the future of your printing operations.